Smart. Fast. Safe.

Ridgistorm-XL Tanks and Chambers. Constructed off-site, delivered on time.

We provide a comprehensive service at our 2,600m2 fabrication facility, creating fully-engineered solutions to precisely match your specific project requirements. We’ll not only help you meet your project deadlines by delivering your ready-to-install, pre-fabricated system to site, but ensure a superior finish every time.

- Manufactured in a factory-controlled environment

- Eliminates wastage associated with on-site construction

- WRc approved

By working with you from the early stages of your project, our skilled and highly experienced technical experts can help with the design and specification of your project to ensure you get the best solution. What’s more, with our Fabrication Service, we’ll deliver your tailor-made system to site, ready to install – saving time and costs in the process.

- Our team of experts can engineer the right solution for your project

- All of our systems are pre-fabricated to the highest quality

- Modular solutions, constructed off-site, delivered ready to install

Manufactured in a factory-controlled environment, our Ridgistorm-XL Tanks and Chambers are made using highly engineered thermoplastic for superior durability, reliability and performance.

- Manufactured to meet specific material requirements

- Strong material that’s also flexible to withstand ground movement

- Non-corrosive and resistant to chemicals

- Lighter in weight but robust and long-lasting

- 100% recyclable at the end of their useful life

As well as ensuring the quality of our systems, our pre-fabricated solutions enable quicker and easier installation on-site – saving time, reducing the added cost of plant material and minimising waste and its costly removal.

- Results in measurable cost savings

- Reduces on-site installation time and costs

As part of our Fabrications Service, we supply pre-fabricated modular solutions with pre-installed connections and components, such as flow control and treatment devices, designed to integrate with other systems on site. This significantly reduces time during installation.

- Can incorporate pre-fabricated integrated components within chambers and manholes, as well as modular fittings and bends

- Ready-to-install man-access solutions integrate at any point in a drainage system

- Delivered as one-piece modular units ready to install on site

Our Tanks and Chambers are manufactured from high quality engineered thermoplastic that’s robust and long-lasting but lighter in weight than traditional materials such as concrete. This makes them easier to lower into place and quicker to install.

- Easier to transport

- Less heavy plant equipment required for installation

- Reduces the need for specialist skills on site

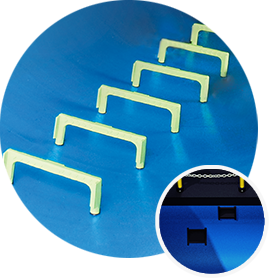

Factory-fitted lifting points can be pre-welded into our chambers and tank fittings as part of our Fabrications Service. Their design assists in the safe handling of our systems when loading, off-loading and installing the products on site – lifting up to 2,500kg.

- Chambers consist of three lifting points to provide stability during handling

- Can be removed after installation without compromising the leak tightness of the chamber

Our fabrications team can pre-fit a range of safety components, including ladders and steps, toe-holds, guardrails and safety chains. This not only helps to reduce installation time and costs, but no welding on site minimises operational Health and Safety risks.

Ridgistorm-XL Guardrail Assemblies can be pre-installed into our manholes and chambers to act as a safety barrier.

- Compliant with Sewers for Adoption, 7th Edition and MCHW F Series

- Prevents the site workers from accidentally falling into the outflow channel

- Pre-fabricated into the chamber, delivered to site as a one-piece modular unit ready to install

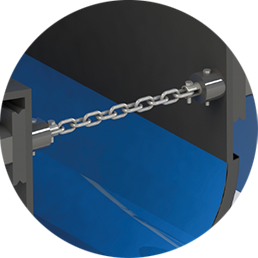

Ridgistorm-XL Safety Chain Assemblies can be pre-fitted to act as a lifeline should a worker accidentally fall into the outflow pipe while in the manhole or chamber, preventing them from being swept further down the pipe.

- Pre-fabricated into the chamber, delivered to site as a one-piece modular unit ready to install

- 3kN breaking strength

- Compliant with Sewers for Adoption, 7th Edition and MCHW F Series

Ridgistorm-XL step rungs and ladders can be incorporated to ensure easy and safe access to chambers and manholes.

- Ladders manufactured to BS EN 14396

- Step rungs manufactured to BS EN 13101

- Delivered to site as a one-piece modular unit ready to install

Manufactured in a factory-controlled environment, our Ridgistorm-XL Tanks and Chambers are made using highly engineered thermoplastic for superior durability, reliability and performance.

- Manufactured to meet specific material requirements

- Strong material that’s also flexible to withstand ground movement

- Non-corrosive and resistant to chemicals

- Lighter in weight but robust and long-lasting

- 100% recyclable at the end of their useful life

Contact Us

Find out how Ridgistorm-XL Tanks and Chambers can enhance your next project.

Tel: +44 (0) 1509 615100

Email: civils@polypipe.com